WayKen Is Revolutionizing Manufacturing Using Rapid Tooling

Rapid tooling, also called prototype tooling or bridge tooling, is a fast and cost-efficient way to carry out low-volume injection molding for plastic parts.

SHENZHEN, GUANGDONG, CHINA, May 24, 2021 /EINPresswire.com/ -- The innovations in the manufacturing sector have contributed to the increased cost-efficient techniques in mass production. In product development, rapid tooling is a vital process for businesses in need of fast turnaround times.

Leading rapid tooling company WayKen is providing these high-quality tooling services for clients in China and beyond. With an experienced team of engineers and flexible production methods, they are a one-stop shop for rapid prototyping and cost-effective rapid manufacturing services.

According to the WayKen CEO, "Our rapid tooling process will get you molded parts quickly and at an affordable cost. At the company, we use production-grade material and state-of-the-art technology for low-volume rapid injection molding."

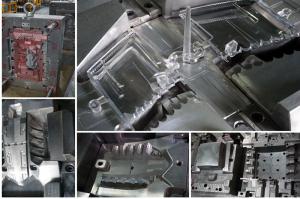

With its main operations in China, the company manufactures tools for its clients that can be used to create products. As a critical process in product development, rapid tooling can develop parts such as rapid injection molds, sheet metal prototype molds, quick rapid die-cast molds, fixtures, and other custom parts.

This technology also creates the necessary parts needed for product testing, also known as soft tooling, prototype tooling, or bridge tooling. Businesses can use these custom parts at the prototyping stage to verify pre-production, design optimization, and functional testing. In addition, clients can use the pieces to seek funding and presenting their new ideas to potential partners.

WayKen prides itself as an expert in key manufacturing processes including, parts surface finishing, CNC machining, EDM machining. With this level of expertise, they can bring your idea to life through rapid tooling and rapid injection molding. Once you customize your order for low-volume plastic parts, they can deliver your product within 2-5 weeks.

For customers who specialize in plastic parts, WayKen is your go-to partner. They use rapid tooling techniques to create plastic molds. By incorporating rapid injection molding, they can manufacture high-quality components for clients to test their prototypes. This process is essential at the initial production phase.

Apart from producing parts, the company uses your business objectives to guide you on the best materials to use. During the rapid tooling process, customers require guidance on the suitable materials to use according to the product needs. The team of engineers is skilled in optimized design, which is essential in revealing issues in the design before mass production. Furthermore, they ensure that the parts are tooled and molded in the most cost-effective way possible.

For clients who are considering rapid tooling, the CEO says, "Compared to conventional tooling, rapid tooling is a good choice for your business. It's more cost-effective, has a faster turnaround and delivery time, and your parts get to be of high quality. If you need a prototype in the next few days, our team of experts will deliver to your specifications."

WayKen's team of engineers can handle any rapid tooling projects according to your material. For example, they can make rapid mold tools from Aluminum 7075, P20, and NAK80 semi-hardened steel and H13 fully-hardened steel. These services also come with surface finishes to ensure your part is of good quality.

Rapid Tooling has a considerable cost advantage for manufacturers and can save up most of the production budget. With these low costs, the manufacturer can make prototypes, new designs, and molds with more flexibility. This process is also advantageous for clients and manufacturers that have tighter budgets.

As most industry players adopt prototype processes before mass production, companies such as WayKen provide rapid tooling services to manufacture molds. With advanced technological methods and a highly qualified team, they are China's go-to manufacturer for all your rapid tooling needs.

About WayKen Rapid Manufacturing Ltd: Headquartered in Shenzhen, China, WayKen's services vary from providing CNC Machining, 3D Printing services, Vacuum Casting, Rapid Tooling to Sheet Metal Processing. Wayken offers CNC milling, CNC turning, drilling, and tapping for various materials, such as metal machining or CNC plastic.

Their key technologies make them stand out in the market. They include Rapid Injection Molding, CNC Prototype Machining, CNC Aluminium Machining, Prototype finishing and painting, Urethane Vacuum Casting.

Tony Gong

Rapid Prototyping Company-AutoProtoWay.com

+86 755 2373 1920

info@waykenrm.com

Rapid Prototyping & Rapid Manufacturing Services

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.